About Us

About Us

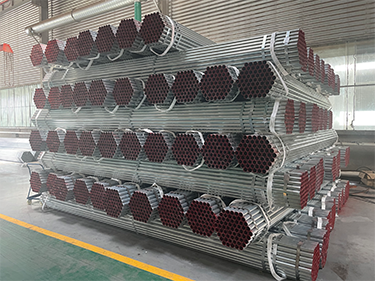

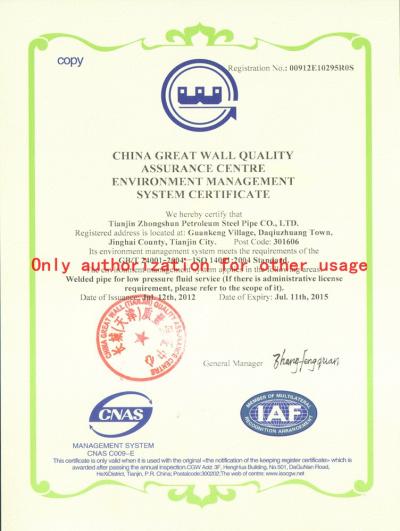

We, Tianjin Zhongshun Petroleum Steel Pipe Co,. Ltd, is an investment group, engaging in steel pipe products manufacturing, exporting, specialized in producing high-tech ERW (Electric Resistance Welded) and SAW (Spiral Submerged Arc welded) and Seamless steel pipes. Zhongshun Group founded in 1995, is a professional manufacturer of petroleum steel pipes in China, covering an area of 300,000 square meters, with investment of USD 37 million in total and more than 450 employees. Equipped with 3 longitudinally H.F. welded pipe production lines, 7 spirally double-side submerged arc welded pipe production lines, 3 anti-corrosion pipe production lines, the company can manufacture 600,000 tons of welded steel pipes per year. |